Specialty services for BIM and ALM

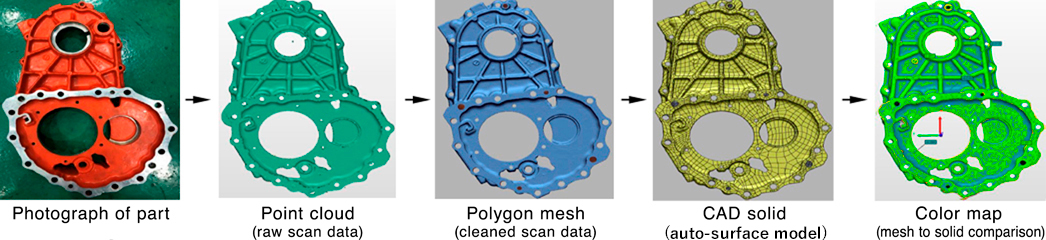

Example of a reverse engineered part:

Simulation plant layout, remodeling, etc.

Galaxy-Eye makes layout change simulation easy by enabling direct manipulation (rotate, transform) of point cloud regions.

Clash detection for moving objects

By setting up an animated clash check from point cloud data, interference regions can be easily identified and saved for future reference.

Plant layout changes made simple

Quickly iterate through candidate layout configurations and save time and labor.

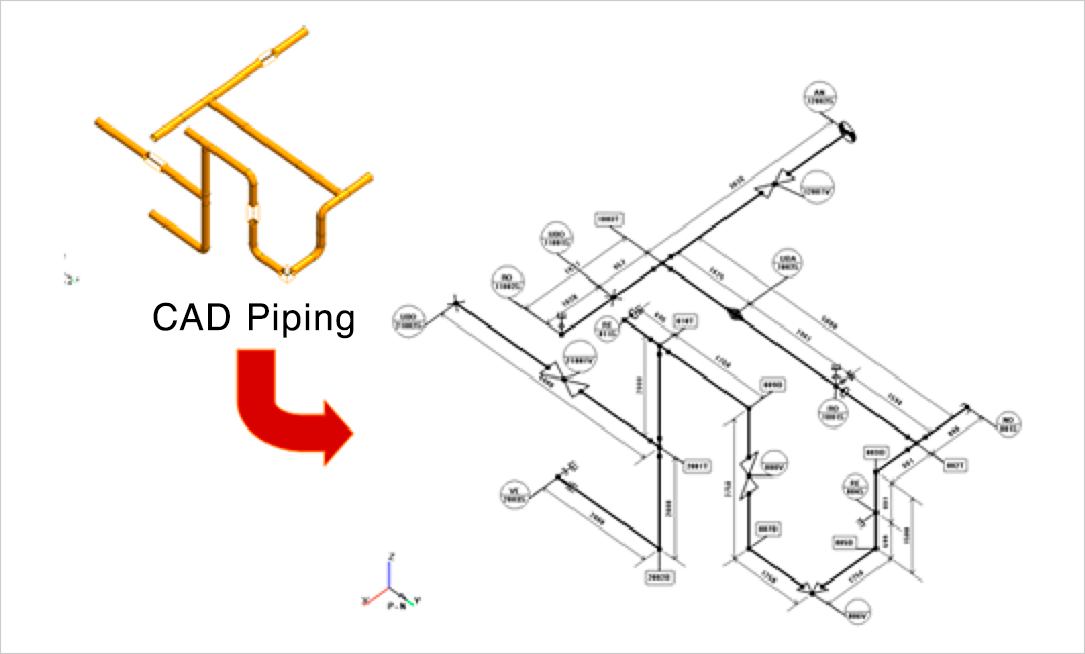

Galaxy-Eye features a library of typical pipe objects for rapid BIM. Supports conversion to isometric drawings.

Galaxy-Eye can extract CAD planes from point cloud data for modeling walls and other flat surfaces.

Point cloud → CAD → Iso-drawing

Supports GD&T annotations, valve symbols, welding symbols, pipe support symbols, and support fitting constraint settings, etc.

Supports output to NASTRAN for FEA.

Example use case

For earthquake code compliance reinforcement planning.

CAD structural steel modeling

Galaxy-Eye features a library of typical structural steel objects for rapid BIM.

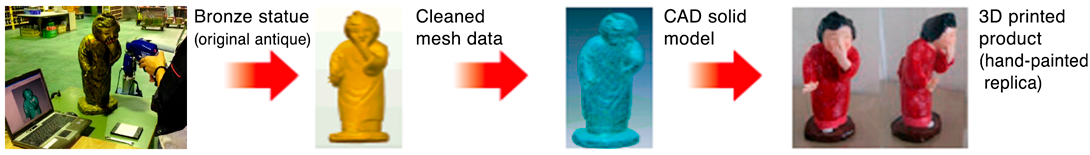

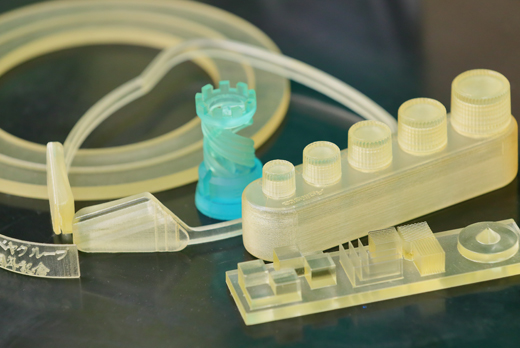

Once we have scanned a target and processed the mesh, we can use the data for ALM on one of our two 3D printers.

Keyence AGILISTA-3200

Keyence AGILISTA-3200 Flashforge GUIDER II

Flashforge GUIDER IIOur printers can output a variety of different materials including transparent resin, heat-resistant resin, silicone rubber, and more. Each material has different properties for different use conditions. If you need highly ductile material that will accept metal fasteners without cracking, we have that. If you need water-resistant material that is highly resistant to deformation, we have that too. Heat resistance, transparency, flexibility, whatever you need, we have the right material for any application. Our printers' max lamination pitch is 15μm, meaning we can print at high resolution for aerospace level precision applications. Before investing in precision machined metal parts made from expensive alloys, print out a prototype with JMS for design validation.

Please describe your project specifications in the form below and we will get back to you in 2-3 business days.